Laboratory

Internal Laboratory

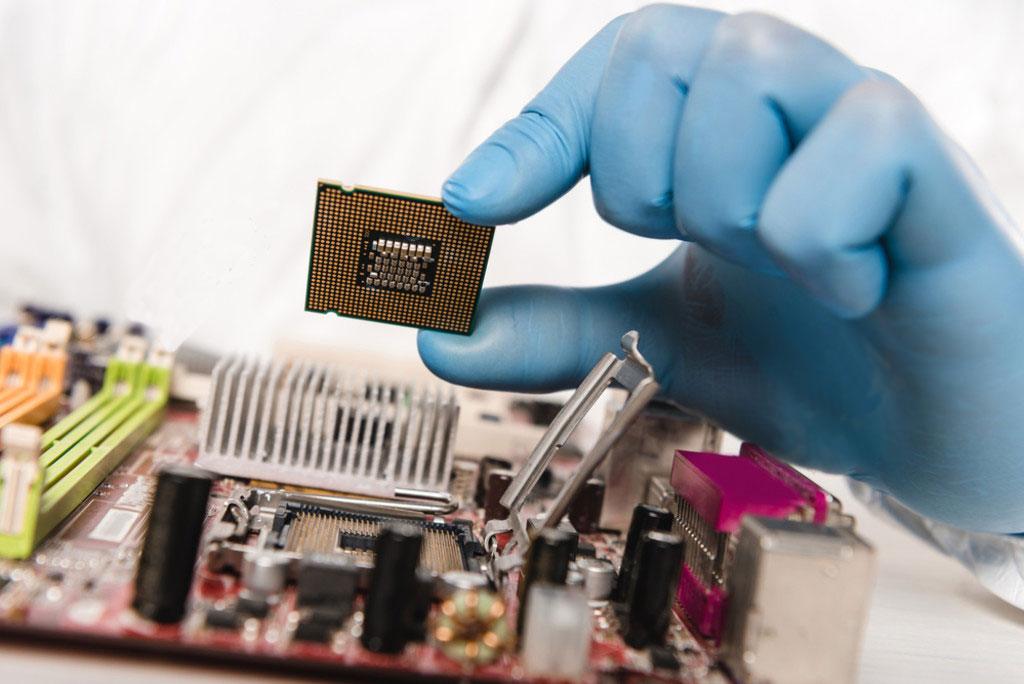

Pursuit of Excellence in Quality

Quality is the cornerstone of Belta in the electronic component distribution industry. We have our own strong QC team and a series of inspection processes for incoming materials. We strive to standardize every inspection process to make commitments to our customers. In the process of continuous improvement, we enrich our database to improve the quality standards of the entire industry.

i. Receiving

i. ReceivingSources come from original factories, agents, and OEM factories.

ii. Outer Packaging and Label Inspection

ii. Outer Packaging and Label InspectionInspect the outer packaging, labels, and silk screen of the goods and compare them with the BELTA database to verify authenticity.

iii. Photo Archiving

iii. Photo ArchivingAll information of incoming materials, part number, D/C, quantity, label, silk screen, and outer packaging are entered into the system to achieve traceability of shipments.

iv. High Magnification Microscope Inspection

iv. High Magnification Microscope InspectionVisual inspection of the IC body to confirm the cleanliness of the pins or BGA.

v. Acetone Marking Test

v. Acetone Marking TestAcetone reagent is used to test the IC MARKING to confirm whether it has been REMARKed.

vi. Solderability Test

vi. Solderability TestSolderability test is performed on the material pins to confirm solderability.

vii. X-RAY

vii. X-RAYPerspective inspection of the internal structure of the IC, and compare with the system database to confirm structural consistency.

viii. Shipment

viii. ShipmentComplete the inspection process and deliver to the customer as soon as possible.